Custom Jewelry Design

Unfortunately, custom jewelry design has become a rarity in the jewelry world today, but it just so happens to be our specialty at Albert Kaz Jewelry. There may be a preconceived notion that custom designed jewelry comes with a high price tag, however, that isn't always true. In fact, the opposite is often the case, since we do all of our work in store, there are no middlemen and our designer has so much experience that he can make suggestions to the design to keep it well within budget. But perhaps the best thing about custom jewelry designs is that they are unique and meaningful pieces of art that can be passed on for generations. Let's take a quick walk through the process.......

The Process

The customer is included throughout the entire custom jewelry design process to ensure that they are pleased with the end result. We work with the customer to first come up with a design based on something they have seen or imagined. After a rough sketch of the design is created, we use the state-of-the-art CAD CAM designing program to create a 3D computer generated image of the design. This image is then transferred to our in store 3D printer, which will print a wax prototype of the design. This prototype will then be casted with whichever metal the customer chooses. Following this step any diamonds or gems will be set, the finished piece will be polished, cleaned, and lastly gift wrapped for the customer when they come to pick it up. Creating your own design is very rewarding and increases the personal value of the piece.

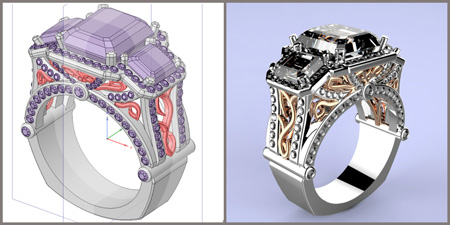

Designing

The designing phase usually takes the longest. But it is essential when it comes to custom design. We use state-of-the-art CAD CAM to accurately create the design. The design can be something that was originally hand drawn, an idea or based on something you have seen. You can schedule an appointment to meet in person to review the design. Or we can correspond via email once the initial design is completed. At this point, you can alter the design to better fit your needs. It is very common for changes to be made. When you review the design, it is imperative that you provide as much feedback as possible about what you like and do not like. The more feedback you give, the faster the process goes. Once you give the go ahead for the design, we will move on to the next stage.

Wax Printing and Casting

In this stage we send the design to our 3D printer, which will create a wax prototype of the design. Once the wax prototype is created it can be casted in the metal that you choose (gold, silver, platinum, etc.) This will create the setting for your design. Should you wish to do so, you will have an opportunity to see the wax design prior to casting.

Choosing Stones

The next step is choosing the right stone(s) for your design and budget. The diamond price will fluctuate based on the Cut, Clarity, Color, and Carat weight of your stone(s). At this point, you will put down a deposit to cover the cost of your stone(s). If your center stone is 1 ct or larger it will come with a certificate from the Gemological Institute of America (GIA).

Polishing, Finishing and Final Purchase

After your stone(s) are set, we will polish and put the finishing touches your custom piece. You will do a final inspection of your purchase. The remaining balance is due once you are satisfied. If you purchase a custom engagement ring you will receive a complimentary appraisal. Custom purchases come with complimentary inspections and cleanings throughout the life of the piece. We offer gift wrapping upon pick up. To keep our prices affordable, we do not offer financing. Visit our gallery page for our latest CUSTOM JEWELRY DESIGNS